Concept, Planning, and Consultancy

We thoroughly analyze the technical and logistical feasibility of each project, defining the necessary processes and systems in detail. To ensure top performance, we evaluate cycle times and availability of machinery. Additionally, we advise our clients from the design phase to maximize the automation potential in production and assembly.

Feasibility analysis

We carry out a technical and logistical feasibility analysis and a precise cost estimation. This way, we guarantee the profitability of the project and strict compliance with delivery deadlines.

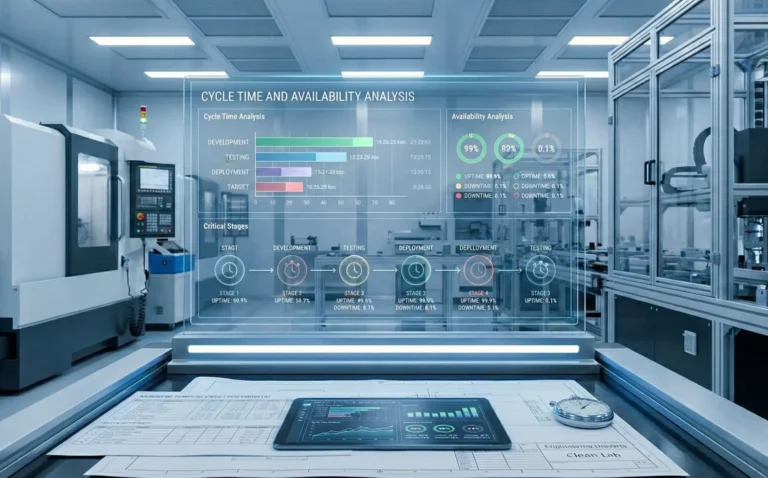

Cycle time and availability analysis

We exhaustively analyze the cycle times and availability at each critical stage of development. In this way, we ensure the achievement of objectives and guarantee the expected results at all times.

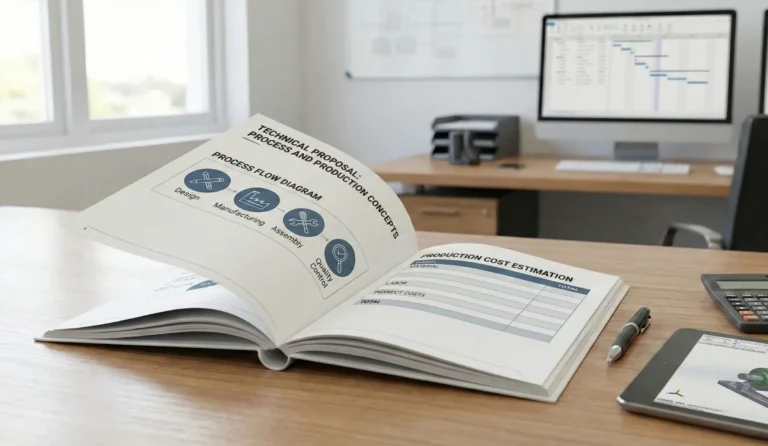

Process and production concepts

We include detailed process and production concepts in every proposal to offer clear visual support to the client and establish a solid foundation for precise cost estimation.

Workstation analysis

We prepare detailed MTM (Methods-Time Measurement) analyses upon request, applicable to both our own equipment and external machinery.

Process optimization

As automation specialists, we offer comprehensive support in the optimization of processes and production cycles to maximize efficiency.

Project Implementation

We implement specific projects in close collaboration with the client, from individual devices to fully automated systems. For the production of components, we work with established partners who guarantee the highest standards of quality and punctuality. Additionally, we perform comprehensive management of each project to rigorously monitor times and costs.

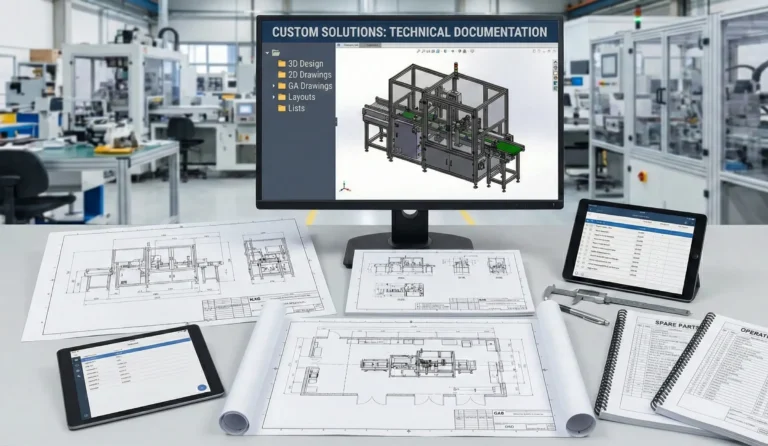

Mechanical design

We design and build custom solutions, systematically delivering all the technical documentation required for each project:

- Detailed 3D design of the solution.

- 2D assembly and production drawings.

- GAB drawings (General Arrangement drawings).

- System layout (Layouts) for plant implementation.

- Parts lists, spare parts, and operating components.

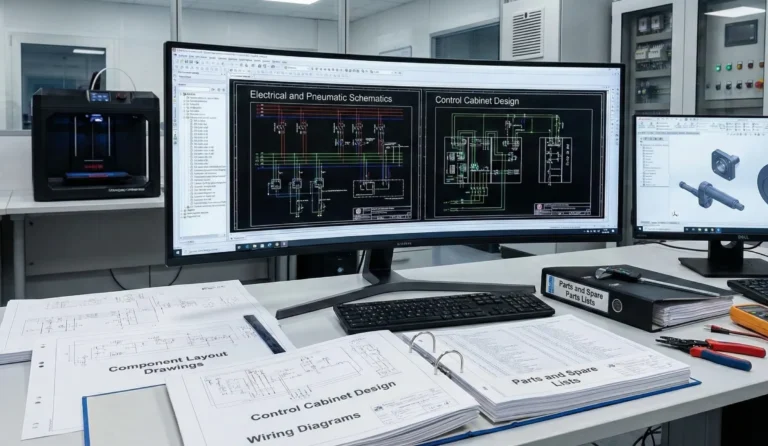

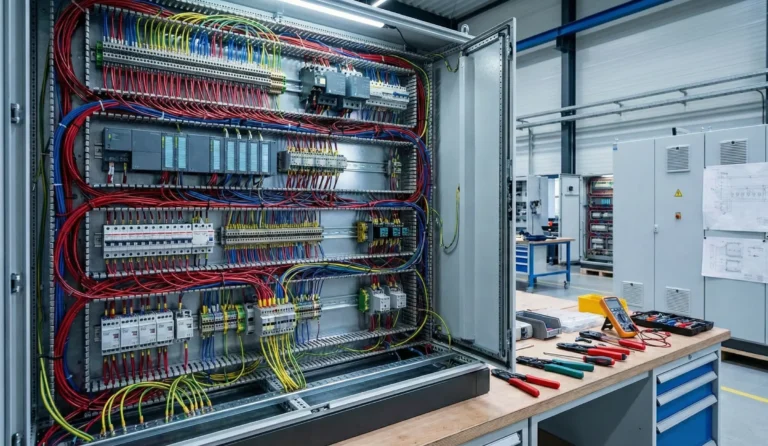

Electrical and pneumatic planning

We integrate requirements and mechanical design to produce, through CAE systems, complete electrotechnical documentation including:

- Electrical and pneumatic schematics.

- Control cabinet design and component distribution drawings.

- Wiring diagrams and detailed parts and spare parts lists.

Control cabinet assembly and wiring

We build everything from individual control cabinets to complete automatic lines, ensuring that every installation strictly complies with European regulations and applicable UL standards for safety and quality.

Programming and commissioning

We develop software solutions based on PLC and PC systems for a wide range of industrial applications:

- Machine control, systems, and robotics.

- Supervisory computers and analysis stations.

- Data collection for production and quality control.

- Expansion or modification of existing systems.

Assembly, delivery, and installation

We have large workshop spaces for the simultaneous assembly and commissioning of various production systems. We take responsibility for the entire logistical process, from delivery to final assembly at the client’s facilities.

Robot programming

We integrate all types of robots and manufacturers in the market according to the specific requirements of each process. Our solutions include:

- SCARA robots and stationary 6-axis arms.

- Mobile robots and systems with a seventh axis for extended reach.

- Pick & Place applications and solutions fully integrated with standard control systems.

Post-Sales Support

We offer worldwide support after equipment delivery, both during the warranty period and after its expiration. We provide various service levels that include both online and on-site assistance. For external equipment, we evaluate maintenance needs and prepare the corresponding offers with maximum speed.

Technical assistance

We quickly resolve any incident and offer continuous support to minimize production downtime. Through direct communication, we guarantee tailored technical solutions to keep your facilities always operational.

Preventive and corrective maintenance

We design preventive maintenance plans to avoid downtime and extend the service life of equipment. We act quickly in the corrective maintenance of any system to restore operation in the shortest possible time.

System expansion and modernization

We specialize in the expansion of systems and equipment, both our own and external. Upon request, we perform optimizations to increase the safety and efficiency of existing production processes.